Thermal Imaging

Thermal cameras can detect anomalies often invisible to the naked eye. Based on knowledge and experience our qualified engineers can accurately identify existing faults as well as predict possible future issues that could save lives. The camera is used to scan an area under inspection, looking for unexpected hot spots. It produces a live image of the heat emitted from the equipment, which can be captured for uploading to a computer for closer analysis, reporting and future trending.

Thermal cameras can detect anomalies often invisible to the naked eye. Based on knowledge and experience our qualified engineers can accurately identify existing faults as well as predict possible future issues that could save lives. The camera is used to scan an area under inspection, looking for unexpected hot spots. It produces a live image of the heat emitted from the equipment, which can be captured for uploading to a computer for closer analysis, reporting and future trending.

Whilst IR cameras are easy to use, the images they produce are best interpreted by an experienced and qualified electrician, since not all electrical hot spots are loose connections.

The Process

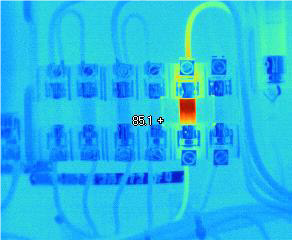

Thermal imaging, or thermography, is the process of using an infrared (IR) camera to look for heat given off in the form of IR energy waves. Excess heat released by electrical cables, switchgear, distribution boards and motors can be indicators of potential problems.

If undetected these problems can lead to failure and can result in expensive production loss or downtime, or in the most extreme of cases, lead to a fire. The image above shows how a poor connection has increased resistance, which has lead to an increase in heat at the connection, and in the wires feeding the connection.

A regular program of thermal imaging, as part of routine maintenance, can highlight potential problems long before any event occurs, allowing for repairs to be planned for in terms of both time and budget.

Applications

Thermography of electrical systems can be used to detect:

- Loose connections

- Overloads

- Phase imbalances

- Corrosion

- High resistance in fuses and switchgear

Thermography of mechanical systems can be used to detect:

- Motor overload

- Worn bearings

- Boiler seal leakage

- Insulation breakdown

- Hydraulic, steam and hot water systems

- Tank levels and insulation

- Valves

Contact us for more details on how we could assist you in managing your electrical and mechanical system risks.